SATEA : Where Quality Innovation Gains Industry Recognition

ASQ’s South Asia Team Excellence Award (SATEA) is an annual award and recognition program. SATEA provides teams an opportunity to assess their performance against an excellence framework. The SATEA Criteria exemplifies quality in action. This is an outstanding program for showcasing the amazing accomplishments of teams across functions to improve quality in every function of their organizations.

SATEA recognizes and celebrates outstanding team achievements across domains of organizations like yours who are increasingly focused on advancing a culture of quality-based practices. Team project entries spanning every sphere of a business entity demonstrates the universal application of this framework.

SATEA aims to be a catalyst for promoting a culture of collaboration, innovation, and excellence within organizations and across industries. This prestigious award acknowledges teams that have displayed exceptional performance, creativity, and effectiveness in addressing challenges.

Introducing Category Awards for domain-specific excellence in:

- Operational Excellence

- Innovation Excellence

- People Management

- Sustainability

- Customer Experience

- Supply Chain Resilience

- Digital & Data Analytics

- Strategic Execution

- Process Management

- CSR & Ethics

This evolution ensures focused recognition for specialized contributions driving holistic success.

At ASQ South Asia, we believe in the power of people to transform organizations. SATEA is our way of amplifying those stories of transformation. Whether you’re a returning champion or a first-time participant, this is your stage to inspire and be inspired.

Driving Project Excellence and Business Value

The SATEA Criteria framework is designed to empower organizations of all sizes, across diverse industries, to benchmark and enhance their project outcomes. By offering a universal approach, the framework facilitates quality improvement initiatives across various functions, regardless of the tools or methodologies employed.

SATEA framework is applied to projects of varied hues and nature to achieve organizational goals. The framework helps drive growth and accelerate business value through quality improvement initiatives across different functions.

Teams that participate benefit from the universal SATEA framework, driving innovation and achieving remarkable results to improve business performance and customer delight. The recognition provides validation for teams implementing quality practices and encourages continuous improvement throughout the organization.

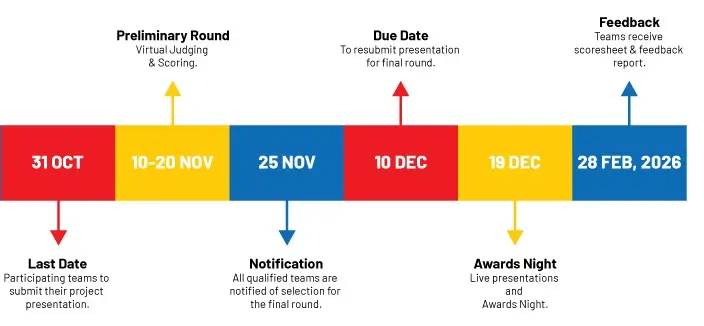

First Round: Preliminary Round Online Live Presentation

Teams submit project presentation aligned with the Team Excellence Criteria showcasing creative, innovative solutions and significant cost savings resulting in enhanced customer satisfaction, product innovation, and team performance. Projects must either be active (still seeing results at the time of submission) or have been completed within the last 2 years and include measurable results. Teams will be invited for virtual live presentation and will be judged by a panel of judges.

Second Round: Final Round Onsite Live Presentation

At the daylong event qualified teams from the preliminary round will make live presentations to the judges for final award qualification. Finalists will showcase their project success stories, offering opportunities to the teams to learn, share, and benchmark from within the industry and across industry. Three-member team per project entry are entitled to attend the Live Presentation.

Scoring and Evaluation

The scoring and evaluation are consensus-based. After the final round, the jury panel will also provide detailed feedback to every participating team.

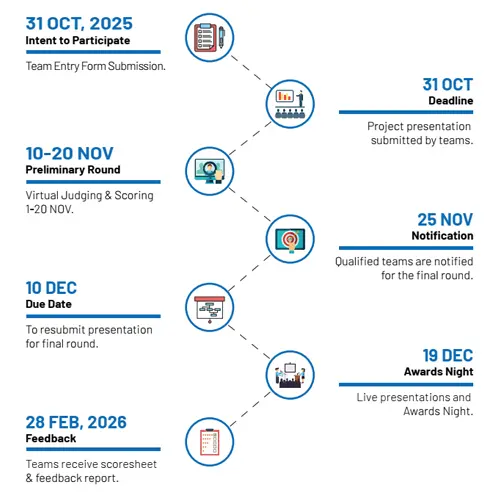

Complete Team Entry Form

Complete and submit team entry form with all required details.

Identify Project(s)

Identify project(s) completed in the last two years that achieved measurable results and that you plan to submit. Projects must either be active (still seeing results at the time of submission) or have been completed within the last 2 years and include measurable results.

Create PowerPoint Presentation

Create a PowerPoint presentation that describes your completed project(s).

Align with Award Criteria

Ensure that any presentation aligns with the Team Excellence Award Criteria.

Submit Presentation & Payment

Submit the presentation with team details & make the payment by September 25th 2025.

Virtual Live Presentation

Teams will be invited for virtual live presentation and will be judged by a panel of judges.

Final Round Notification

Qualified teams (from the preliminary-round entry process) will be notified of selection for the final round 15th November 2025.

Confirm Participation

Teams confirm their participation to present live at New Delhi.

Live Event in New Delhi

Teams participate in live presentations, live judging & scoring, sharing best practices, learning, and getting recognition at an event organized on 19th December 2025 at New Delhi.

PLATINIUM AWARD

This award honors the highest-scoring team for their outstanding performance and collaborative problem-solving, setting a benchmark for excellence in team results.

JURY CHOICE AWARD

This honor recognizes an exceptional project, carefully selected by the jury for its outstanding impact, innovation, and strategic execution, showcasing a benchmark for excellence.

The Category Awards are here to celebrate outstanding team projects across all departments—Operations, HR, Supply Chain, IT, and more. Gold, Silver, and Bronze awards will be presented in each category to honor teams demonstrating commitment to quality, innovation, and impact.

Innovation Excellence

Projects showcasing original ideas or novel improvements in products or services that create significant value, differentiation, or competitive advantage in the market

Customer Experience

Initiatives that enhance customer satisfaction through improved experiences, insights from feedback, or programs that place customer needs at the heart of decision-making.

Sustainability

Projects addressing environmental, social, and governance goals, or promoting diversity and inclusion, with long-term value creation and responsible business practices.

Supply Chain Resilience

Projects to optimize sourcing, procurement, logistics, or supplier collaboration, leading to improved efficiency, cost savings, and stronger supply chain resilience.

Digital & Data Analytics

Projects leveraging data analytics, machine learning, or AI to solve problems, gain insights, automate processes, or drive strategic decisions and innovation

People Management

Initiatives that boost employee engagement, build collaborative cultures, or foster cross-functional teamwork for improved productivity and organizational alignment

Operational Excellence

Projects aimed at enhancing operational efficiency through continuous improvement or digital transformation, driving measurable improvements.

Strategic Execution

Projects focused on effective implementation of organizational strategy through robust policy deployment such Total Quality Management (TQM) practices, and alignment of goals across teams.

Process Management

Initiatives that enhance process efficiency, consistency, and performance through structured KPI frameworks, process design, standardization, and continuous process improvement methodologies.

CSR & Ethics

Projects driven by leadership commitment, focusing on ethical governance, strategic vision, or impactful corporate social responsibility efforts that align with organizational values.

Hall of Fame

- 2025 Tata Consultancy Services - Enterprise CBO Unit

Project: Improvement in Tier 2 HR Ops Employee Satisfaction

The project targeted a major service gap in Tier-2 HR Operations, where ESAT had dropped to 56%. Using DMAIC, the team implemented a suite of 13 process and digital innovations, including AI-driven quality checks, automated knowledge recommendations, RPA for bulk actions, workflow automation, and a 24×7 self-service portal. These were complemented by creative coaching and empathy frameworks. The initiative improved accuracy to 99%, reduced TAT to 48 hours, and increased ESAT to 90%, delivering over USD 83M in value through productivity and experience-driven impact.

TOTAL VALUE DELIVERED

OPERATIONAL ACCURACY

- 2024 Max Life Insurance Co. Ltd

Project: D2S (Digital to Sales)

The project focused on building a unique, customer-centric, digitally enabled cross-sell business model, with an end-to-end journey from need-based product offering to sales conversion, by leveraging Digital Assets. The project is aligned with our values of Customer Obsession, Growth Mindset, and Collaboration. Using DMADV tools like Affinity Diagram, Control Impact matrix, FMEA and POC, we established D2S as a scalable model poised to deliver 60 Cr. incremental revenue over the next two years.

INCREMENTAL REVENUE

YEARS

- 2023 Tata Power

Project: Improvement of Flue Gas Exit Temperature

The winning project enhanced Flue Gas Exit Temperature, reducing it from 142.72°C to 138.53°C. The team used Multiple Regression Fit Model and Optimize Response tool for process/logic modification inputs. Implementation of individual corner SADC Dam per Operation was pivotal in achieving results. The project delivered substantial savings of 6.54 Crore/year for One Unit Operation, reinforcing Tata Power's commitment to operational excellence and continuous improvement

FLUE GAS EXIT TEMPERATURE REDUCED

CRORE/ YEAR SAVED

- 2019 eClerx Services

Project: Increasing Transactional Sales Rate

eClerx CHAT-Repair process deals with customers reaching client website for account related/Repair issues and supporting customer in resolution through Chat. We also pitch customers by offering to add services like Internet, Cable, phone and home security in addition to existing products. This project aims to improve Transitional Sales Rate (%) from the baseline of 0.91% to 1.75% of total Chat interactions. This will improve Client revenue and also enhance profitability and business prospects for eClerx.

TRANSITIONAL SALES RATE IMPROVED

- 2018 TATA Steel

Project: Coke Moisture Reduction

Tata Steel produces steel using Blast Furnace-LD [BF-LD] route. In BFs, the raw material is converted into liquid hot metal using coal and coke as fuel. Coke is a hardened version of coal with reduced moisture, is produced in-house through carbonization process which costs ~40% of steelmaking process. A model was developed to reduce moisture content in coke by 10%. The model is well-validated with plant and leading to reduction in water consumption by 3.38 Mgd and CO2 emission by 0.6%.

REDCTION IN WATER CONSUMPTON

REDCED CO2 EMISSION

- 2017 Ashok Leyland

Project: Reliability Improvement of Reaming Machines

This project supported Ashok Leyland's market share growth by reducing breakdown time at vehicle assembly line. Using DOE, Regression, Capability studies and Gemba observations, we identified root causes through structured problem solving. The initiative produced an additional 3802 vehicles, improving revenue by INR 5703 Million and helped machine manufacturer improve product reliability by 81%, embodying "We celebrate your success as a team

ADDITIONAL VEHICLES MANUFACTURED

MILLION REVENUE INCREASE

- 2016 eClerx Services

Project: SPMD Automation

This project focused on improving product catalogue coverage from 60% to 80% for a major computer technology company's online parts and upgrade operations. The team applied Lean Six Sigma methodology and used Brainstorming, Fishbone, Process Door Analysis, Hypothesis testing, and Control Charts. Upon project completion, the team processed 300% additional volumes, saved AHT by 50% and improved process quality by 70%. Subsequently, the catalogue coverage was increased by 21%, offering the client additional revenue of $18.2 million.

REDUCTION IN AHT (AVERAGE HANDLE TIME)

MILLION ADDITIONAL REVENUE

PREVIOUS PARTICIPANTS

Join industry leaders for this transformative event

"*" indicates required fields

Request a Copy of the 2025 ASQ South Asia Team Excellence Award Criteria

Thank you for your interest in ASQ SA’s Team Excellence Award Criteria. Please complete the Form to receive a copy of the Criteria to be used in preparing your presentation for the South Asia Team Excellence Award competition.

PARTICIPATION FEES

Choose Your Entry Option

Organisation, Team and Project Information Complete all the fields in the Team Entry Form. Information you provide on this form will be used for preparing your team finalist award and/or used in promotional materials. We reserve the right to edit your project description.

Please do not type in all capital letters.

"*" indicates required fields

American Society for Quality India Pvt. Ltd

A-24/9, Ground Floor,

Mohan Cooperative Industrial Estate,

Mathura Road, New Delhi-110044

- +91 11 46783399 / 40793571/2

- +91 11 40793573

- asqindia@asq.org

Mobile : 9818419394

ASQ South Asia Team Excellence Award (SATEA)

Frequently Asked Questions

Interested teams can submit their entry form either:

- Online at ASQ India website

- Through email to asqindia@asq.org

- Complete and submit entry form

- Identify projects completed in the last two years that achieved measurable results

- Create a PowerPoint presentation describing your completed project(s)

- Align presentation with the Team Excellence Award Criteria

- Submit presentation and payment by September 25th, 2025

- Virtual live presentation - teams will be invited and judged by expert panel

- Team Entry Form

- PowerPoint presentation aligned with SATEA Criteria

- Company Logo

- Payment confirmation

- INR 30,000 per team entry (domestic teams)

- USD 400 for international teams

- Discount available for non-profit organizations

- Group discounts available

- Fees are non-refundable

- Projects must be completed within the last 2 years OR currently active with measurable results

- Projects should be beneficial for the organization and customers

- Must be well-aligned with SATEA criteria

- Any methodology (Six Sigma, Lean, etc.) can be used

- Innovation projects are welcome

- No specific project size limitations

Preliminary Round:

- Live virtual presentation

- 25 minutes presentation + Q&A session

- All participating teams are invited

- Judged on 0-3 rating scale

Final Round:

- In-person presentation in New Delhi

- 15 minutes presentation

- 24 teams selected for finals

- Judged on 5-point scale across quantitative and qualitative factors

| Score | Scale Definition |

|---|---|

| 0 | Criteria are not addressed |

| 1 | Criteria addressed through verbal explanation, but documentation not available |

| 2 | Criteria addressed with partial evidence and linkage |

| 3 | Criteria addressed with complete evidence and linkage |

| Factor Type | Evaluation Criteria |

|---|---|

| Quantitative | Financial Performance, Operational Efficiency, Customer Satisfaction |

| Qualitative | Market Transformation Capability, Innovation Potential, Social and Economic Impact |

Preliminary and Final round presentations carry 70-30 weightage respectively.

- Trophy and certificates

- Recognition by a global brand at national/regional level

- Gold, Silver & Bronze winners in each category

- One overall Platinum Award winner

- All finalists receive certificates

- Winner's ceremony

- Media coverage and press releases

- Feature on ASQ India website & social media

- Team recognition by management and industry peers

- Recognition as the only criteria-based team award

- Enhanced organizational reputation

- Opportunities for knowledge sharing and networking

- Career advancement for team members

- Strengthened quality culture within the organization

- 2024 - Max Life Insurance

- 2023 - Tata Power Company Ltd

- 2019 - eClerx Services

- 2018 - Tata Steel

- 2017 - Ashok Leyland

- 2016 - eClerx Services

For complete details, visit the Hall of Fame.

- Not aligning with the SATEA Criteria

- Not covering all Sections & Items of the Criteria

- Not providing enough evidence for project claims in the presentation

Primary Contact Methods:

- Email: satea@asq.org

- General Inquiries: asqindia@asq.org

- Website: ASQ India Contact

- Registration: SATEA Registration

South Asia Team Excellence Awards

Recognizing and celebrating outstanding team achievements across South Asia