Recertification

Getting Certified

Resources

Certification is a mark of excellence. It demonstrates that the certified individual has the knowledge to ensure the quality of products and services. Certification is an investment in your career and in the future of your employer.

You made the effort to pass the certification exam in the first place – now maintain it by being recertified with ASQ. Maintaining your certification secures the investment you’ve already made in your career.

Please send us a scanned copy of following documents, preferably in a 2 files. Point 1 separate file & point 2 & 3 separate file:

1.Recertification Journal Application duly filled in (form download button). (Don’t delete any page bcz there is some coding)

2.Letter from company stating you are an employee since ………… (date).

3.Certificates or letters from organizations for having attended training, workshops or conferences in last three years. Alternately, you can send a letter from your HR with the list of trainings attended in last three years, along with number of hours for each training. This should total at least 72 hours of training.

4.Nothing special to be done for synching the documents. Just mention this in your mail and pay.

Please take a screen shot of the fee transaction and email to us.

- Member (1 recert): Rs. 9350 + 18% GST

- Member (2 or more recerts): Rs. 11,900 + 18% GST

- Non-member: Rs. 13,600 per recertification + 18% GST

Account Holder Name: AMERICAN SOCIETY FOR QUALITY INDIA PVT LTD

Current Account Number: 31459090888

IFSC/RTGS code (Indian Financial Security code): SBIN0003219

MICR code: 110002117

Branch Address: STATE BANK OF INDIA, M-2 SOUTH EXTENSION PART-2, NEW DELHI

ASQ Recertification Application submission Process

Once your document is ready then please take a screen shot of the fee transaction and email to us at asqindia@asq.org required document list is given below.

- Journal Application

- Supporting documents, in one single pdf file, multiple files will not be processed

- Payment details.

New to recertification in 2025:

Streamlined & simplified RU categories

— Professional Development, Employment, & Giving Back

Addition of Giving Back category,

granting the ability to claim recertification units for volunteering & mentoring

Removed maximum RU limit for Professional Development activities,

allowing for more credit to be claimed for courses, conferences, webinars, & more

Discontinued outdated categories

(proctoring & multimedia)

Recertification Detailed Overview

DO I NEED TO RECERTIFY?

How to know if you need recertification

ASQ requires that you recertify the following certifications every three years to ensure that you maintain the same level of knowledge demonstrated in your first exam.

To check your current certification information, please login. Your certifications will display there. The information will include expiration dates, status of pending certifications, and exam result information for retakes.

| Biomedical/Medical Device Auditor | Calibration Technician | Manager of Quality/Organizational Excellence |

|---|---|---|

| Pharmaceutical GMP Professional | Quality Engineer | Six Sigma Black Belt |

| Master Black Belt | Software Quality Engineer | Food Safety and Quality Auditor |

| ASQ/DON Lean Six Sigma Black Belt | Quality Auditor | Reliability Engineer |

CONTINUING COMPETENECE

ASQ definition of continuing competence – maintaining certification

Continuing Competency refers to the demonstration of specified levels of knowledge, skills, or ability not only at the time of initial certification but throughout an individual’s professional career.

ASQ mandates maintenance of one’s credential through activities that reinforce continued competence through supported continued training in the knowledge and methods of the field. Maintaining your ASQ certification is crucial to your professional growth, fluency and currency within the industry and is a mandatory requirement of your certification. In accordance with ISO 17024 Standards for Conformity Assessment, recertification conditions shall ensure that there is impartial evaluation to confirm the continuing competence of the certified person. To maintain the integrity of your certification, ASQ requires that you recertify every three years-either by journal or by exam. If you do not recertify, your certification will lapse and ASQ will no longer recognize you as “certified”.

After initial certification, you must carry out specific professional development requirements in order to recertify every three years and provide documentation in support. All activities must fall/tie into at least one area of the Body of Knowledge (BOK) for your certification(s).

Certified individuals must comply with all recertification requirements to maintain use of the respective credential and its associated acronym. Certified individuals may not make misleading, deceptive, or confusing statements regarding their certification status. If an individual allows their certification to fall into lapsed/expired status, he or she must immediately discontinue use of the associated acronym and is prohibited from stating or implying certification is current.

RECERTIFICATION REQUIREMENTS

What you need to recertify

ASQ requires that you recertify certain professional certifications once every three years to ensure that you maintain the same level of knowledge demonstrated in your first exam.

CREDENTIAL HOLDERS MUST:

- Obtain 18 recertification units (RUs) within a three-year recertification period.

Or

- Retake the certification exam at the end of the 3-year recertification period.

Note: You have a 60-day “grace period” from your recertification date to recertify by Journal. After the 60-day grace period, you will need to recertify by exam. If you do not recertify by exam within 1 year from your recertification date – your certification will expire/decertify and you will need to reapply for initial certification.

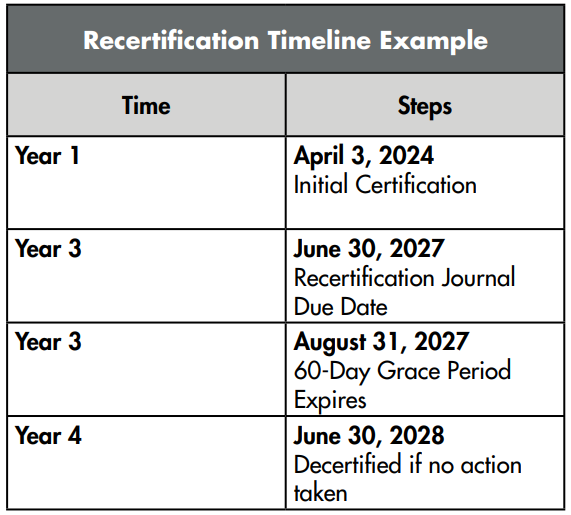

RECERTIFICATION TIMELINE AND FEES

Timeline and Fees

ASQ requires that you recertify the following certifications every three years to ensure that you maintain the same level of knowledge demonstrated in your first exam. ASQ maintains two primary recertification due dates annually, June 30th & December 31st. Your recertification cycle will sync to one of these two checkpoints based on when you originally sat for your exam. Exams taken from January through June will sync to the June 30th deadline, while exams taken July through December will sync to the December 31st deadline. An example timeline is displayed below.

RECERTIFYING BY JOURNAL FEES

Fees to recertify by journal/application:

| ASQ Member | ASQ Non-Member |

1 certification | $90 | $130 |

2 or more certifications (Synchronization) | $110 total | $130 each |

RECERTIFYING BY EXAM FEES

Fees to recertify by exam:

| ASQ Member | ASQ |

CMQ/OE | $418 | $518 |

CSSBB | $418 | $518 |

CQE, CQA, CSQE, CRE, | $383 | $483 |

CCT | $297 | $397 |

CMBB | $1399 | $1399 |

All prices listed are subject to change without notice.

SYNCHRONIZING

Synchronizing my Certifications

If you hold multiple ASQ certifications you can “synchronize” them and renew them all at once by submitting a single recertification journal instead of separately renewing different certifications with different recertification dates.

To synchronize two or more certifications, all you need to include is documentation for the 18 recertification units required to recertify the 1 certification that is currently due. You’re not required to provide additional evidence for any of the other certifications you are trying to synchronize. If the certification that is currently due is approved, we will adjust all your other certifications to recertify at the same time as the certification currently due. For future recertification, you only need to provide a total of 18 recertification units for all synchronized certifications.

Example of How Synchronization Works

| Certification | Date Exam Passed | Current Recertification Dates | Future Recertification Date | ||

|---|---|---|---|---|---|

| Quality Auditor | 12/03/07 | 12/31/13 | 06/30/16 | ||

| Reliability Engineer | 03/04/10 | 06/30/13 | 06/30/16 | ||

| Software Quality Engineer | 10/02/11 | 12/31/14 |

|

RECERTIFICATION ACTIVITIES

Qualifying Recertification Activities

- Professional Development (No Maximum RU Limit)

Certification – 2.0 RUs per ASQ Certification, 1.0 RUs per other certifications (Please note: certificates of course completion do not qualify as professional certification earned through demonstration of a specific skill or competency.)

Continuing Education – Learner 0.1 RU per hour, Instructor 0.1 RU per hour. Duplicate credit cannot be claimed with employment.

Publishing & Reviewing – Book: Author or Editor 4.0 RUs, Co-Author 2.0 RUs; Article: Author 1.0 RU, Co-Author 0.5 RU; Presented Paper/PPT: 1.0 RU;

Meetings/Events (online or in-person) – Conferences: 1.0 RU per day; Workshops: 1.0 RU per day; Seminars: 0.1 RU per hour; Meetings: 0.1 RU per hour;

- Employment (10.8 RU Max)

Full-time Employment: 0.3 RU per month, 3.6 RU per year; Part-time Employment: 0.15 RU per month, 1.8 RU per year;

- Giving Back (6 RU Max)

Volunteering – 0.1 RU per hour, 1.0 RU max;

Professional Membership – 0.5 RU per year, 1.5 RU max;

Mentoring – 0.1 RU per hour, 1.5 RU max;

Committees – 1.5 RU per year, 4.5 RU max;

- Professional Development (No Maximum RU Limit)

Please review the Recertification Handbook for more detailed descriptions of qualifying recertification activities.

HOW TO APPLY FOR RETIREMENT STATUS

Apply for Retirement Status

If you are an ASQ certified professional who has retired from active employment and have reached age 59-1/2, you may request that a ‘retired’ status be designated on your certification records. Your certification(s) will then be left in good standing and will not lapse or be deleted from your certification records.

Download a ASQ Certification Retirement Status Application and return your completed form via email or standard mail in order to apply. The application form contains additional instructions and details regarding the ASQ certification retirement process.